|

|

| Blak-Tac Armour is the latest in metal surface treatment technology. Put into use in the firearms industry exclusively by Olympic Arms, Blak-Tac is the answer to many problems that have plagued the minds and rifles of AR style tactical shooters and 1911 for decades. | |

|

|

|

So what is Blak-Tac? Blak-Tac is a proprietary metal coating used on both stainless steel and carbon steel (it is not compatible with Aluminum). Although this process is used in other industries, Blak-Tac is an exclusive product to Olympic Arms for use on firearms. As below, Blak-Tac is a metal treatment that actually restructures, hardens, and smooths the surface molecules of metal. It creates a matte black lubrous, and almost polished surface. |

|

|

|

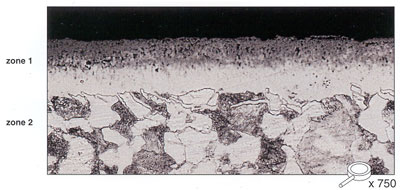

| Shown at a magi fa cation level of 750X, the photo above reveals the results of Blak-Tac metal treatment to steel bar stock. Creating 2 zones in the metal, the surface becomes more dense, harder, smoother, and much less likely to chip, crack, or break. Being smoother the likelihood of galling is practically eliminated, and friction is reduced dramatically.

Blak-Tac is a treatment that combines thermochemical diffusion in hot chemical baths, with a finishing treatment (a passive impregnation of an organic sealant) to produce a surface having exceptional resistance to wear, scuffing, galling, corrosion and fatigue. Blak-Tac is a duplex process that heat-treats the metal while at the same time treating its surface. This replaces a two-step process with one step that is much more efficient. Blak-Tac also eliminates any risk of failure due to Hydrogen embrittlement -a major problem with many other applied metal coatings. Blak-Tac creates no dimensional difference, and is totally control able with regards to depth of treatment and hardness. Dependant on material be treated, Blak-Tac can penetrate from as little as 10, to as much as 25 microns, and with some allows much deeper yet. |

|

(What little discoloration that is seen on the Blak-Tac treated barrel and bolt carrier is nothing more than residue that has chemically electrolyted from the untreated carrier onto the other parts in the same bath. These deposits wiped right off with out fingers!) |

Blak-Tac will be used by Olympic as a complete replacement for hard chrome finish. Notice the bore of the bolt carrier to the left. After 7 days in a 30% salt solution, the center bolt carrier (a new parkerized carrier with a chrome bore) is rusted inside and out! The bolt carrier to the left, and SS 1911 barrel to the right (both treated to the Blak-Tac process) are rust free. |

|

Places where galling, scuffing, wear, seizure or corrosion are encountered, Blak-Tac is the ideal metal treatment. You can consider Blak-Tac a complete replacement for popular metal coatings such as hard-chrome, nickel, cadmium, zinc, Teflon and more. Blak-Tac; The Future of firearms metal treatments. |

|